Nutritive composition and labelling compliance of pre-packaged fresh eggs from Croatian producers

L. Dergestin Bačun, T. Lešić, N. Kudumija, A. Vulić and J. Pleadin*

Lidija DEGESTIN BAČUN1, bacun@veinst.hr; Tina LEŠIĆ1, lesic@veinst.hr, orcid.org/0000-0001-6773-9473; Nina KUDUMIJA1,

kudumija@veinst.hr, orcid.org/0000-0001-6144-6514; Ana VULIĆ1, vulic@veinst.hr, ORCID: https://orcid.org/0000-0002-9379-7236;

Jelka PLEADIN1* (corresponding author), pleadin@veinst.hr, orcid.org/0000-0002-0768-0462

1 Analytical Chemistry Laboratory, Department of Veterinary Public Health, Croatian Veterinary Institute, 10000 Zagreb, Croatia

![]() https://doi.org/10.46419/cvj.57.2.9

https://doi.org/10.46419/cvj.57.2.9

Abstract

The nutrient composition makes the chicken egg a perfectly balanced food in the human diet, serving as a dietary source of protein, fat, and other nutrients. Easily accessible, eggs can be found in almost every household. Although manufacturers are not required to provide nutritional information on egg packaging, many have recognised the benefits of highlighting the nutritional declaration on their products. The aim of this study was to analyse the nutritional composition of different grades of eggs from different producers and farming systems, and to assess compliance with the nutritional tables declared on the products. The study covered a period of five years, from 2020 to 2024, during which 107 packs of fresh chicken eggs from five different Croatian producers were analysed, including barn and cage reared eggs, and different weight classes (M and L). The results showed that the eggs from Croatian producers have high nutritional value and nutrition tables listed on the packaging are accurate for each evaluated class of eggs, for all five producers. In addition, all product labels complied with the requirements for nutritional information in the form of nutritional tables set by the European Union regulations.

Key words: chicken egg; nutritive composition; product declaration; egg production

Introduction

As defined in Commission Delegated Regulation (EU) 2023/2465, eggs of hens refer to eggs in shell laid by Gallus gallus hens, which are suitable for direct human consumption or for the preparation of egg products. Eggs are a highly valuable foodstuff with a remarkably efficient protein utilisation rate of 94%, contributing significantly to body proteins (Senčić and Samac, 2017). Compared to other food sources (meat and fish), they are the most favourable source of animal protein in the diet. Eggs contains many essential nutrients, and in particular are a good source of essential amino acids, fatty acids, vitamins such as B12, D and A, and also choline, lecithin, iron, phosphorus, and selenium, and bioactive components such as lutein and zeaxanthin. The nutrients in the egg are well-balanced and cover the dietary needs of children and adults, particularly since they also contain biologically active components (Réhault-Godbert et al., 2019).

Eggs also contain compounds such as lumiflavin, lumicrome and sulforaphane, known to inhibit the replication of carcinogenic viruses and prevent normal cells from turning into cancer cells (Laza, 2017). Although they contain cholesterol, recent studies suggest that cholesterol from eggs does not cause hypercholesterolaemia or cardiovascular disease in the majority of the population. Eggs are considered functional foods if, in addition to their basic nutritional function, they positively influence one or more functions in the body and improve overall health or reduce the risk of disease (Radanović, 2023). Due to their high nutrient density, eggs are particularly suitable for the diets of vulnerable populations, including children, the elderly, chronically ill patients, and pregnant women (Senčić and Samac, 2017).

The quality of eggs can be assessed in various ways by measuring both external and internal parameters. External characteristics of eggs include size, mass, shape and surface colour. According to Commission Delegated Regulation (EU) 2023/2465, the following quality characteristics are defined for fresh eggs: shell and cuticle, air chamber, yolk, albumen, embryo, foreign bodies, and odour. Internal quality refers to various indicators such as the pH value of the yolk and the egg white, Haugh units, degree of ageing, and content of essential chemical components (Ivanković et al., 2018).

Since the introduction of the requirement for nutritional information in the form of nutritional tables in 2016, many egg producers have voluntarily opted to include this information on their packaging. However, according to Regulation (EU) No 1169/2011 on the provision of food information to consumers, unprocessed products consisting of a single ingredient or a single category of ingredients, such as fresh eggs, are exempt from the mandatory provision of nutritional information. However, manufacturers have recognised the benefits emphasising the nutritional declarations of their products. The market standards and rules on the implementation of market standards for eggs of the Gallus gallus species produced and marketed in the Republic of Croatia are defined by the Ordinance on market standards for eggs (OG 80/2024).

The labelling of packaged eggs is regulated by Commission Delegated Regulation (EU) 2023/2465. Under this regulation, eggs intended for human consumption are categorised either as class A, suitable for direct sale to consumers, or class B, intended primarily for the food industry. Class A eggs are further divided into four weight classes: XL – extra large (weight ≥ 73 g), L – large (≥ 63 g and < 73 g), M – medium (≥ 53 g and < 63 g) and S – small (< 53 g). The following information must be clearly and visibly indicated on the packaging of class A eggs: the name of the packing centres where the eggs are packed and, where appropriate, repacked; the quality class with the indication “class A” or simply “A” in conjunction with the words “fresh” or “fresh eggs”; the weight class (S, M, L, XL); the best-before date in accordance with Article 9(1)(f) of Regulation (EU) No 1169/2011 with the indication “best before” followed by the date; the indication “washed eggs” for eggs that have been washed in accordance with Article 4 of Regulation (EU) No 2023/2465; and consumer advice to store the eggs in a cool place after purchase. In addition, the farming method must be indicated in a visible place with terms such as “free-range egg”, “barn eggs” and “enriched cages”; for organic farming, the terms are defined in Article 30(1) of Regulation (EU) 2018/848 of the European Parliament and of the Council.

The aim of this study was to analyse the nutritional composition of eggs of different classes from different Croatian producers and farming systems, and to assess compliance with the nutritional tables declared on the packaging. Furthermore, the study aimed to assess the compliance of the product declaration with relevant legislation in the European Union.

Materials and Methods

Samples

A total of 107 packs of M and L grade (class A) fresh chicken eggs were included in the study. Samples were delivered to the laboratory for compositional analysis between January 2020 and December 2024. The eggs were produced by five Croatian producers (P1 – P5) and were originally packaged in packaging of 10 eggs and labelled with the intention of being placed on the market.

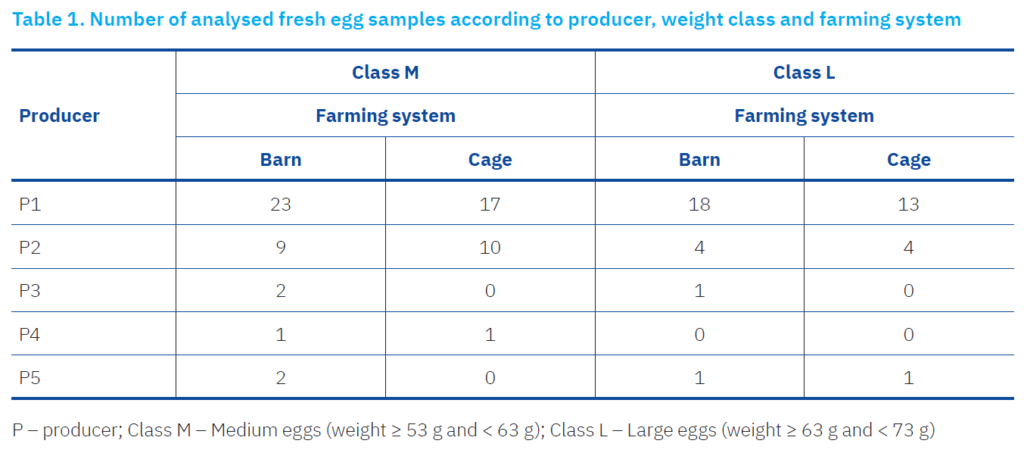

Table 1 shows the number of the samples analysed in this study for nutritional composition, and categorised by producer, weight class, and farming system.

Samples preparation

Upon receipt at the laboratory, the packages were inspected and examined for appearance and odour prior to homogenisation. In the second step, fresh eggs were prepared for analyses of nutritional parameters as the pull of six eggs from the same package. They were homogenised at 4,000 rpm for 8 sec using a Grindomix GM 200 apparatus (Retsch, Haan, Germany). Water content was analysed immediately after homogenisation and the remainder of the samples was stored at 4–8°C until the completion of all analyses.

Analysis of nutritional values

Analysis of nutritional values (g/100 g) were performed by applying validated standard and internal analytical methods. Determination of water (ISO 1442:1997) and ash (ISO 936:1998) content was performed by gravimetric methods with the use of an oven (UF75 plus, Memmert, Schwabach, Germany) and muffle furnace (Program Controller LV 9/11/P320, Nabertherm, Lilienthal, Germany). Crude protein content was determined using the Kjeldahl method (HRN ISO 937:1999), which involves the destruction of organic matter at 420°C with use of a block digestion unit (Unit 8 Basic, Foss, Hilleroed, Denmark) followed by distillation and titration using the Vapodest 50s (Gerhardt, Königswinter, Germany). Crude fat content was determined by the Soxhlet method (HRN ISO 1443:1999), which includes fat hydrolysis and fat extraction with petrol ether on the extraction device (Soxtherm 2000, Gerhardt, Königswinter, Germany). Fatty acid methyl esters were prepared from the extracted fats according to the ISO 12966-2:2015, using hexane as a solvent and 2N methanolic potassium hydroxide solution for transmethylation. The prepared methyl esters were analysed with gas chromatography by implementation of the standard ISO 12966-4:2015 and use of gas chromatograph with flame ionization detector 7890B (Agilent Technologies, USA), as described by Kudumija et al. (2024). Sodium content was analysed using the flame atomic absorption spectroscopy (AAS) technique with a 200 Series A4 instrument with SPS 4 Autosampler (Agilent Technologies, Santa Clara, USA). Sugar content was measured enzymatically using the analytical kit Enzytec Liquid Sucrose/D-Glucose/D-Fructose (R-Biopharm, Darmstadt, Germany) according to the manufacturer’s instructions. Carbohydrate content was calculated by subtracting the water, protein, fat and ash content from the total value (100%). The energy value was calculated using conversion factors defined in Annex XIV of Regulation 1169/2011 (carbohydrates 17 kJ/g or 4 kcal/g; proteins 17 kJ/g or 4 kcal/g; fats 37 kJ/g or 9 kcal/g) and expressed both in kJ and kcal.

Results and Discussion

The study included pre-packaged M and L grade eggs from five different producers and two types of farming systems. Sample numbers were not evenly distributed among producers, with the most samples supplied by Producer 1. Additionally, more samples were analysed from the M weight class than the L class; however, the number of samples from each farming system was approximately equal within the same weight class.

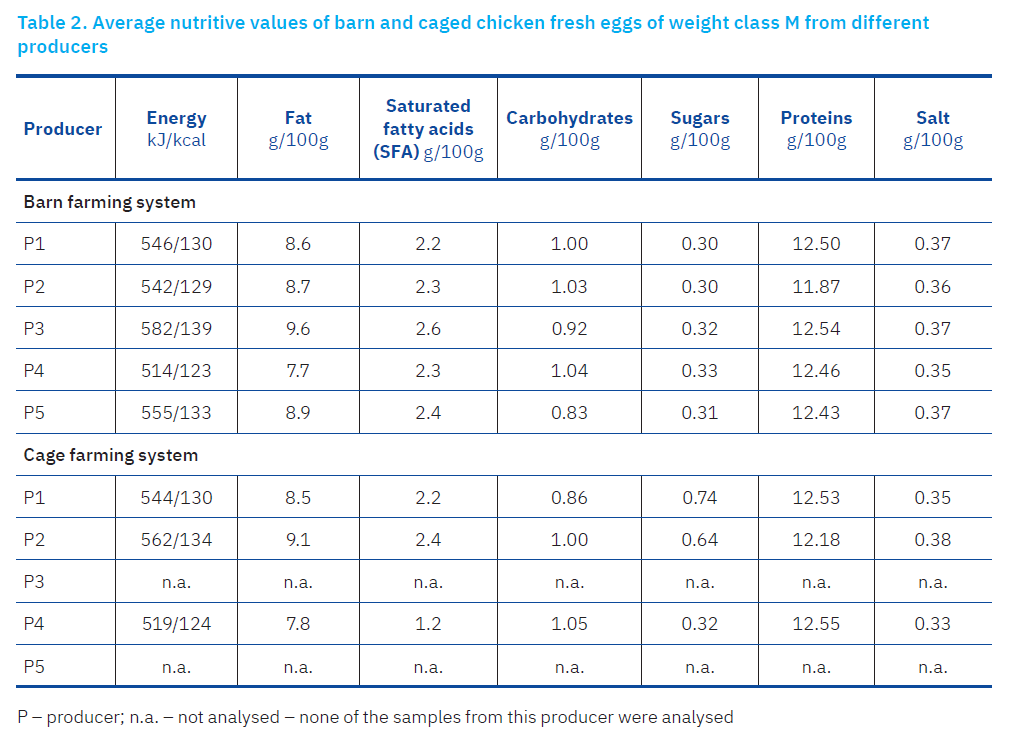

Table 2 shows the average nutritive values determined for pre-packaged eggs of weight class M from different producers and farming systems.

The eggs of class M from both rearing systems exhibited similar energy values, ranging from 514 to 582 kJ. The highest energy value was found in eggs from Producer 3 in the barn rearing system (582 kJ), while the lowest value was recorded for eggs from Producer 4 in the same system (514 kJ). The fat content ranged from 7.7 g/100 g to 9.6 g/100 g, with the highest value observed in barn eggs. The content of saturated fatty acids (SFA) remained consistent, except for eggs from Producer 4 in the cage rearing system, which contained only half the SFA content of the other eggs. Carbohydrate and sugar contents were negligible, at around 1 g/100 g and 0.3 g/100 g, respectively. Protein content was consistently at or above 12 g/100 g in all samples analysed, while the salt content remained below 0.5 g/100 g. Table 3 shows the average nutritional values for pre-packaged eggs of weight class L from different producers and farming systems.

The energy values of the eggs from both rearing systems in weight class L ranged from 502 to 582 kJ, which is lower compared to the eggs in weight class M. For the L weight class eggs, the highest energy value was calculated for cage eggs from producer 5 (582 kJ), while the lowest value was from cage eggs from producer 1 (502 kJ). Fat content ranged from 8.3 g/100 g to 9.4 g/100 g, with the highest value found for cage eggs, which differs from the results observed for M weight eggs. SFA content was between 2.1 g/100 g and 2.4 g/100 g and was similar in both husbandry systems. Carbohydrate content was negligible at around 1 g/100 g, as was the sugar content, which was between 0.20 g/100 g and 0.89 g/100 g. Protein content was comparable to the results for eggs of M weight class and ranged from 11.90 g/100 g to 13.05 g/100 g.

When evaluating the nutritional values of all the analysed pre-packaged eggs, the results of the analysis were in accordance with the nutritive table declared on the package. In addition to nutritive values, additional components of the product declaration were also considered in relation to Regulation (EU) No. 1169/2011. No infringements relating to consumer information were identified on any package included in the study, and therefore all packages were compliant with the legislation.

Conclusion

All analysed egg samples were compliant with the European Union regulations regarding permissible deviations from the values stated in the nutrition declaration on the packaging. The data indicate the high nutritional value of eggs available on the market and good production practises of Croatian producers, showing that great attention is paid to the quality nutrition of laying hens, their health and breeding methods. Product labels of all analysed egg samples were also compliant with the European Union legislation, indicating good production practice.

References [… show]

Nutritivni sastav i sukladnost označavanja pretpakiranih svježih jaja od hrvatskih proizvođača

Lidija Degestin Bačun1, bacun@veinst.hr; Tina LEŠIĆ1, lesic@veinst.hr, orcid.org/0000-0001-6773-9473; Nina KUDUMIJA1, kudumija@veinst.hr, orcid.org/0000-0001-6144-6514; Ana VULIĆ1, vulic@veinst.hr, ORCID: https://orcid.org/0000-0002-9379-7236; Jelka PLEADIN1* (dopisni autor), pleadin@veinst.hr, orcid.org/0000-0002-0768-0462.

1 Laboratorij za analitičku kemiju, Odjel za veterinarsko javno zdravstvo, Hrvatski veterinarski institut, 10000 Zagreb, Hrvatska

Nutritivni sastav čini kokošje jaje savršeno uravnoteženom namirnicom u ljudskoj prehrani, koja služe kao izvor bjelančevina, masti i drugih hranjivih tvari. Zbog povoljne dostupnosti, jaja se mogu naći u gotovo svakom kućanstvu. Iako proizvođači nisu obvezni navesti nutritivne informacije na pakiranju jaja, prepoznali su prednosti isticanja nutritivne deklaracije na svojim proizvodima. Cilj je ovog istraživanja bio analizirati nutritivni sastav različitih vrsta jaja od različitih proizvođača odnosno farmi te procijeniti usklađenost s nutritivnim tablicama navedenim na proizvodima. Istraživanje je obuhvatilo razdoblje od pet godina, od 2020. do 2024., tijekom kojeg je analizirano 107 pakiranja svježih kokošjih jaja od pet različitih hrvatskih proizvođača, uključujući jaja iz štala i kaveza, te različitih težinskih razreda (M i L). Rezultati su pokazali da je nutritivni sastav jaja koje proizvode hrvatski proizvođači visoke vrijednosti i u skladu je s vrijednostima navedenim u nutritivnim tablicama na pakiranju za svaki ocijenjeni razred jaja, kao i za svih pet proizvođača. Ujedno, sve ocijenjene deklaracije proizvoda bile su u skladu sa zahtjevima za navođenjem nutritivnih informacija u obliku nutritivnih tablica, utvrđenim po propisima Europske unije.

Ključne riječi: kokošje jaje, nutritivni sastav, deklaracija proizvoda, proizvodnja jaja